Sculptor David Marshall

Sculpture is a dedication, not a career -this primordial necessity, this gene of creativity has shaped and motivated my life for the last fifty years. I am fascinated by the paradoxical nature of peoples relationship to the natural and industrial world. My subconscious has a predilection for natural phenomena -geological formations, ice patterns, fossils and degradation, the random forms of nature where no lines are straight and where sensory information comes from imperfections.

Through the casting process I have continually attempted to replicate nature while combining modern technology as a creative contrast – mixing brass and aluminium “one off” castings with lathe shavings, laser cuttings, railroad ties or agricultural and automotive materials – and establishing what I believe is a distinctive and very personal three dimensional language. This is my reaction to modernism, minimalism and all the other “isms” imposed by our increasingly depersonalized, machine arbitrated, IT society.

The impact and presence of a sculpture and its relationship to the environment should not be a conscious calculation but rather an instinctive feel of balance and space, a tactile attraction and a form of three D drawing. The sensory beauty of primitive natural materials – to transform them in original ways has been my basic reason for existing and continues to provide a fascinating artistic challenge.

My latest glasswork shown here has been in collaboration with Steamboat Springs Artist Jennifer Baker.

Development Process

CREATION / DESIGN. Faithfulness to the design. Economically and technically feasible. Preliminary economic study. PLANS / TECHNICAL INSTRUCTIONS. Interpretation and compilation of plans and graphic information to carry out the model. Final materials, casting methods, subsequent use, etc. MODEL / PROTOTYPE a work of art, handmade, in different supports (wood, pasta, clay, iron, etc.) depending on the use and the materials in which the print run will be made. The design is faithfully reproduced, in turn facilitating subsequent casting. CASTING. MATERIALS – BRASS / ALUMINUM. No bronze, no tin. Ingots or different proportions of recycled material are used depending on what is desired. CASTING METHOD. SAND. Method used by the Romans since the 3rd century BC. It is the method that allows the necessary print runs to be reproduced faithfully to the models used. Ancestral tools, earth, fire. Several people. Long-suffering, laborious, careful. CRAFTSMANSHIP – MANUALITY – CARE. FITTING/WELDING/ASSEMBLY. Once the piece has cooled, it is filed, deburred, adjusted, assembled, straightened, etc., according to its subsequent use (also milling, turning, etc.). POLISHING. Once assembled, it undergoes up to 5 different polishing, grinding, etc. procedures, entirely manual, until the piece is as seen: Lapping, Taping, Grinding, Polishing, and Shining. CLEANING AND FINISHING. Cleaning, assembly, Sealing, and authentication. QUALITY CONTROL. According to the initial technical specifications, measurements, verticality, etc. ASSEMBLY OF THE WORK.

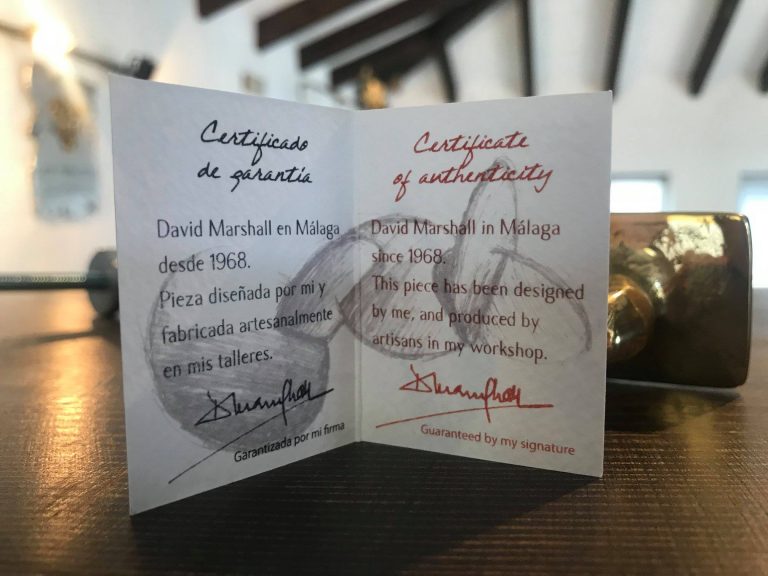

Certificate of authenticity David Marshall